4.3.3 Automation

Your production lines are partially integrated. Therefore low automation on one line will hinder automation on another. A line's effective automation is 50% of its automation rating plus 50% of the lowest automation of all production lines. If a production line has an automation of 8.0, and the lowest automation of all the lines is 4.0, the first production line will have an effective automation of 6.0.

(8.0 * 0.5) + (4.0 * 0.5) = 6.0

The lowest possible automation rating is 1.0; the highest possible rating is 10.0. As automation levels increase, the number of labor hours required to produce each unit falls.

At an automation rating of 1.0, labor costs are highest. Each additional point of automation decreases labor costs approximately 10%. At a rating of 10.0, labor costs fall about 90%.

At an automation rating of 1.0, labor costs are highest. Each additional point of automation decreases labor costs approximately 10%. At a rating of 10.0, labor costs fall about 90%.

Labor costs increase each year because of the Annual Raise in labor’s contract.

Despite its attractiveness, two factors should be considered before raising automation:

- Automation is expensive: At $4.00 per point of automation, raising automation from 1.0 to 10.0 costs $36.00 per unit of capacity;

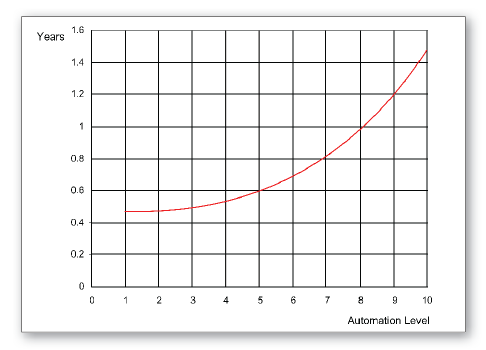

- As you raise automation, it becomes increasingly difficult for R&D to reposition products short distances on the Perceptual Map. For example, a project that moves a product 1.0 on the map takes significantly longer at an automation level of 8.0 than at 5.0 (Figure 4.4). Long moves are less affected. You can move a product a long distance at any automation level, but the project will take between 2.5 and 3.0 years to complete.