Page 3 of 5

People are needed to manufacture the products, so production decisions affect the labor cost of each unit. Each product line has a 1st Shift capacity, that is, the number of products that can be produced each year with a single 8-hour shift.

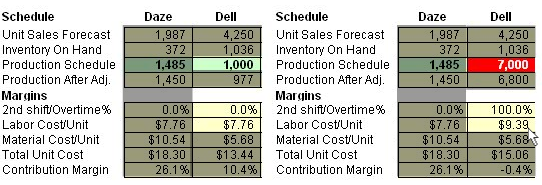

When schedules are less than or equal to the 1st Shift capacity, a 2nd Shift is not needed. However, when schedules exceed the first shift capacity, a 2nd Shift is hired.

Wages for 2nd Shift workers are 150% of 1st Shift wages.

Increasing 1st shift capacity for your production lines can reduce 2nd shift labor costs, but it can be an expensive investment.