The Research and Development (R&D) department oversees invention and redesign. It develops the innovations needed to keep the company ahead of the competition. R&D is responsible for the “product” portion of the 4 P’s of Marketing (“product, price, place and promotion”). This makes R&D an essential part of any marketing process.

Your R&D Department invents new products and changes specifications for existing products. Changing size and/or performance repositions a product on the Perceptual Map. Improving performance and shrinking size moves the product towards the lower right on the map (see “2.1.4 Positioning”).

Your R&D decisions are fundamental to your Marketing and Production plans. In Marketing, R&D addresses:

- The positioning of each product inside a market segment on the Perceptual Map

- The number of products in each segment

- The age of your products

- The reliability (MTBF rating) of each product

In Production, R&D affects or is affected by:

- The cost of material

- The purchase of new facilities to build new products

- Automation levels (The higher the automation level, the longer it takes to complete an R&D project.)

All R&D projects begin on January 1. If a product does not have a project already underway, you can launch a new project for that product. However, if a project begun in a previous year has not finished by December 31 of last year, you will not be able to launch a new project for that product (the decision entry cells in the R&D area of the Capstone Spreadsheet will be locked).

4.1.1 Changing Performance, Size and MTBF

A repositioning project moves an existing product from one location on the Perceptual Map to a new location, generally (but not always) down and to the right. Repositioning requires a new size attribute and/or a new performance attribute. To keep up with segment drift, a product must be made smaller (that is, decrease its size) and better performing (that is, increase its performance).

Positioning Costs

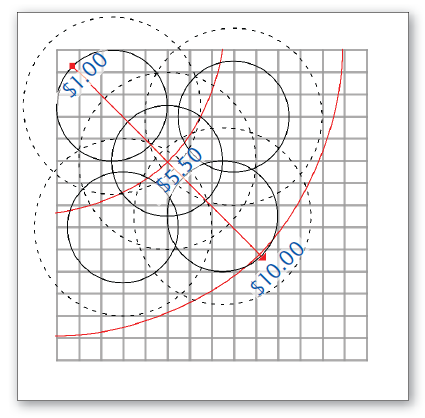

Positioning affects material costs (Figure 4.1). The more advanced the positioning, the higher the cost. At the beginning of the simulation, the trailing edge of the Low End fine cut has the lowest positioning cost of approximately $1.00; the leading edge of the High End fine cut has the highest positioning cost of approximately $10.00.

Reliability (MTBF) Costs

The reliability rating, or MTBF, for existing products can be adjusted up or down. Each 1,000 hours of reliability (MTBF) adds $0.30 to the material cost. A product with 20,000 hours reliability includes $6.00 in reliability costs:

($0.30 * 20,000) / 1,000 = $6.00

Your customers associate MTBF across your product line. Therefore, a low MTBF rating for one product will affect the perception of other products. A product’s effective MTBF is 80% of its MTBF plus 20% of the lowest MTBF in the product line. If a product has an MTBF of 22,000 hours, and the lowest MTBF in the product line is 14,000 hours, the effective MTBF for the first product will be 20,400 hours.

(22,000 * 0.8) + (14,000 * 0.2) = 20,400

Improving positioning and reliability will make a product more appealing to customers, but doing so increases material costs.

Material costs displayed in the spreadsheet and reports are the combined positioning and reliability (MTBF) costs.

Inventing Sensors

New products are assigned a name (click in the first cell that reads NA in the name column), performance, size and MTBF. Of course, these specifications should conform to the criteria of the intended market segment. The name of all new products must have the same first letter of the company name.

The Production Department must order production capacity to build the new product one year in advance. Invention projects take at least one year to complete.

All new products require capacity and automation, which should be purchased by the Production Department in the year prior to the product’s revision (release) date. If you don’t buy the assembly line the year prior to its introduction, you cannot manufacture your new product!

It is not possible to produce new products prior to the revision date. A new product with a revision date of July 1 will be produced in the second half of the year. The capacity and automation will stand idle for the first half of the year.

4.1.2 Project Management

Segment circles on the Perceptual Map move at speeds ranging from 0.7 to 1.3 units each year. You must plan to move your products (or retire them) as the simulation progresses. Generally, the longer the move on the Perceptual Map, the longer it takes the R&D Department to complete the project.

Project lengths can be as short as three months or as long as three years. Project lengths will increase when the company puts two or more products into R&D at the same time. When this happens each R&D project takes longer. Assembly line automation levels also affect project lengths. R&D project costs are driven by the amount of time they take to complete. A six-month project costs $500,000; a one-year project costs $1,000,000.

Sensors will continue to produce and sell at the old performance, size and MTBF specifications up until the day the project completes, shown on the spreadsheet as the revision date. Unsold units built prior to the revision date are reworked free of charge to match the new specifications.

If the project length takes more than a year, the revision date will be reported in the next Capstone Courier. However, the new performance, size and MTBF will not appear; old product attributes are reported prior to project completion.

When products are created or moved close to existing products, R&D completion times diminish. This is because your R&D Department can take advantage of existing technology. It is important to verify completion dates after all decisions have been entered. Usually you want repositioning projects to finish in less than a year. For example, consider breaking an 18 month project into two separate projects, with the first stage ending just before the end of the current year and the second ending halfway through the following year.

4.1.3 A Sensor’s Age

It is possible for a product to go from an age of 4 years to 2 years. How can that be? When a product is moved on the Perceptual Map, customers perceive the repositioned product as newer and improved, but not brand new. As a compromise, customers cut the age in half. If the product’s age is 4 years old, on the day it is repositioned, its age becomes 2 years old. Therefore, you can manage the age of a product by repositioning the product. It does not matter how far the product moves. Aging commences from the revision date.

Changing MTBF alone will not affect a product’s age.

Age criteria vary from segment to segment. For example, if a segment prefers an age of two years and the product’s age approaches 3 years, customers will lose interest (see Figure 3.4). Repositioning the product drops the age from 3 to 1.5 years and customers will become interested again.

Log into the Capstone Spreadsheet and click the Decisions menu. Select Research & Development. To change a product’s performance, enter a number in the New Pfmn cell; to change its size, enter a number in the New Size cell. To change the reliability rating, enter a number in the MTBF cell. As you vary the specifications, observe the effect upon the revision date, project cost, material cost and age.

The Rehearsal Tutorial’s R&D Tactics show you how to run the department. Log in at the Capsim website and go to Getting Started for information about the Rehearsal.