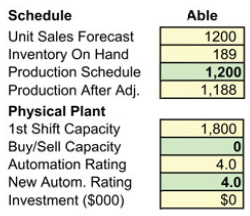

The Production Department schedules manufacturing runs for each product. At the start of the simulation, your production plant has five lines with room for three more. Each assembly line is unique to the product it manufactures. You cannot move a product from one assembly line to another because automation levels vary and each product requires special tooling. Production schedules for each product should consider Marketing’s forecasts and any inventory left over from the previous year.

4.3.1 Capacity

First shift capacity is defined as the number of units that can be produced on an assembly line in a single year with a daily eight hour shift. An assembly line can produce up to twice its first shift capacity with a second shift. An assembly line with a capacity of 2,000,000 units per year could produce 4,000,000 units with a second shift. However, second shift wages are 50% higher than the first shift.

Each new unit of capacity costs $6.00 for the floor space plus $4.00 multiplied by the automation rating. The Production spreadsheet will calculate the cost and display it for you. Increases in capacity require a full year to take effect– increase it this year, use it next year.

Capacity can be sold at the beginning of the year for $0.65 on the dollar value of the original investment. You can replace the capacity in later years, but you have to pay full price. If you sell capacity for less than its depreciated value, you lose money, which is reflected as a write-off on your income statement. If you sell capacity for more than its depreciated value, you make a gain on the sale. This will be reflected as a negative write-off on the income statement (see 6.3 Income Statement).

The dollar value limit of capacity and automation purchases is largely determined by the maximum amount of capital that can be raised through bond issues plus excess working capital. See 4.4 Finance.

4.3.2 Discontinuing A Sensor

If you sell all the capacity on an assembly line, Capstone® interprets this as a liquidation instruction and will sell your remaining inventory for half the average cost of production. Capstone writes off the loss on your income statement. If you sell all but one unit of capacity, your inventory will not be liquidated and it can be sold for full price.

4.3.3 Automation

Your production lines are partially integrated. Therefore low automation on one line will hinder automation on another. A line’s effective automation is 50% of its automation rating plus 50% of the lowest automation of all production lines. If a production line has an automation of 8.0, and the lowest automation of all the lines is 4.0, the first production line will have an effective automation of 6.0.

(8.0 * 0.5) + (4.0 * 0.5) = 6.0

Automation levels are given a scale of 1.0 to 10.0. The lowest automation level is 1.0; the highest level is 10.0. At the start of the simulation, all assembly lines have an automation level between 3.0 and 5.0. As automation levels increase, the number of labor hours required to produce each unit falls.

At an automation rating of 1.0, labor costs are highest. Each additional point of automation decreases labor costs approximately 10%. At a rating of 10.0, labor costs fall about 90%.

Labor costs increase each year because of the Annual Raise in labor's contract.

Despite its attractiveness, two factors should be considered before raising automation:

- Automation is expensive: At $4.00 per point of automation, raising automation from 1.0 to 10.0 costs $36.00 per unit of capacity;

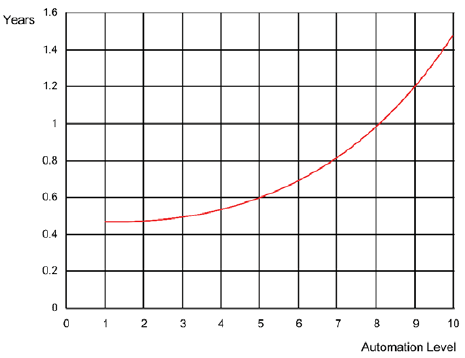

- As you raise automation, it becomes increasingly diffi cult for R&D to reposition products short distances on the Perceptual Map. For example, a project that slightly moves a product 0.7 on the map takes significantly longer at an automation level of 8.0 than at 5.0 (Figure 4.3). Long moves are less affected. You can move a product a long distance at any automation level, but the project will take between 2.5 and 3.0 years to complete.

4.3.4 Changing Automation

For each point of change in automation, up or down, the company is charged $4.00 per unit of capacity. For example, if a line has a capacity of 1,000,000 units, the cost of changing the automation level from 5.0 to 6.0 would be $4,000,000. Reducing automation costs money. If you reduce automation, you will be billed for a retooling cost. The net result is you will be paying money to make your plant less efficient. While reduced automation will speed R&D redesigns, by and large it is not wise to reduce an automation level. Changes in automation require a full year to take effect– change it this year, use it next year.

Login to the Capstone Spreadsheet and click the Decisions menu. Select Production. Use this area to enter for each sensor:

- A Production Schedule

- Increases in first shift capacity (Put a positive number in Buy/Sell Capacity.)

- Decreases in first shift capacity (Put a negative number in Buy/Sell Capacity.)

- Changes in automation level (Enter a number in New Automation Rating.)

The Rehearsal Tutorial covers Production decisions. See the website’s Decisions area for complete information about the Rehearsal Tutorial.